Life Cycle Analysis/EPD — Carved Bamboo Plywood

Life Cycle Analysis/EPD — Carved Bamboo Plywood

Environmental Product Declaration

Carved Bamboo Plywood

Smith & Fong

| General Information 📍394 Bel Marin Keys Boulevard, Novato, CA 94949 ☎ 866-835-9859 ✉ info@plyboo.com | 🌐 plyboo.com |

|

Reference Standards

| Standard(s): | ISO 14025, ISO 14040, ISO 14044, ISO 21930:2017 |

| Core PCR: | UL PCR for Building-Related Products and Services Part A v.4, ISO 21930:2017 Date of issue: March 01, 2022 |

| Sub-category PCR: | UL Part B: North American Structural and Architectural Wood Products v.1.1 Date of issue: October 21, 2019 Valid until: October 21, 2024 |

| Sub-category PCR review panel: | Contact Smart EPD for more information. |

| General Program Instructions: | Smart EPD General Program Instructions v.1.0, November 2022 |

Verification Information

| LCA Author/Creator | Maria Amaya | maria.amaya@beath.us |

| EPD Program Operator | Smart EPD | info@smartepd.com | www.smartepd.com | 585 Grove St., Ste. 145 PMB 966, Herndon, VA 20170, USA |

| Verification | Independent critical review of the LCA and data, according to ISO 14044 and ISO 14071: External Nicole Kennard | Consultant | nicolejjk.17@gmail.com Independent external verification of EPD, according to ISO 14025 and reference PCR(s): External Anna Lasso | Smart EPD | anna.lasso@smartepd.com |

Limitations, Liability, and Ownership

Environmental declarations from different programs (ISO 14025) may not be comparable. Comparison of the environmental performance of products using EPD information shall be based on the product’s use and impacts at the building level, and therefore EPDs may not be used for comparability purposes when not considering the whole building life cycle. EPD comparability is only possible when all stages of a life cycle have been considered. However, variations and deviations are possible. Example of variations: Different LCA software and background LCI datasets may lead to differences results for upstream or downstream of the life cycle stages declared.

The EPD owner has sole ownership, liability, and responsibility for the EPD.

Organization Information

Smith & Fong (S&F) was founded in 1989 on the premise that bamboo offered unique opportunities and solutions to some of the world’s social and environmental challenges. S&F began with laminated bamboo boxes and accessory items, integrating form and function, aesthetics and utility. Within four years, S&F had begun manufacturing bamboo flooring and quickly exhausted manufacturing capacity at their Taiwan facility. Shortly after moving operations to China, S&F converted a tea-processing plant and began producing bamboo flooring there. In 1996, S&F developed a bamboo panel product, introducing the first such product to the North American market. Since then, S&F has continued to develop the laminate bamboo panel product, introducing new sizes, uses and applications for this versatile and highly sustainable material.

Further information can be found at: plyboo.com

Product Description

Bamboo plywood panels can be used in a wide range of applications both commercial and residential. Applications include cabinetry and casework, furniture, store fixtures and displays, wall and ceiling panel systems, doors and many other applications where plywood is typically utilized.

Further information can be found at: plyboo.com

Product Information

| Declared Unit: | 1 m3 |

| Mass: | 690 kg |

| EPD Type: | ❌ Industry Average ✔ Product Specific |

Averaging: This product-specific EPD was developed based on primary annual manufacturing data for bamboo plywood products. The EPD represents products manufactured at one facility. This is deemed to be an accurate representation of an average bamboo plywood product within this product category.

Plants

📍China Facility: Zhejiang, China

📍California Facility: Indio, CA, USA

Product Specifications

| Product Classification Codes: | UNSPSC – 30103604 Masterformat – 06 10 00 Masterformat – 06 22 00 EC3 – Wood -> Plywood and OSB Sheathing Panels |

| Thickness to achieve Functional or Declared Unit: | 0.006 – 0.038 m |

| Density: | 690 kg/m3 |

| Moisture Content: | 6-9 % |

Material Composition

| Material/Component Category | Origin | % Mass |

|---|---|---|

| Bamboo | None | 95 |

| Adhesive | None | 5 |

| Packaging Material | Origin | kg Mass |

|---|---|---|

| Corrugated Boardbox | None | 3.54E/01 |

| Shrink Wrap | None | 1.81E-03 |

| Wood Pallet | None | 1.17E+02 |

| Particle Board | None | 1.15E+02 |

| Medium Density Fiberboard | None | 5.69E-02 |

| Metal Binding | None | 2.30E+00 |

Hazardous Materials

No regulated hazardous or dangerous substances are included in this product.

EPD Data Specificity

| Primary Data Year: | 2022 |

| Manufacturing Specificity: | ✔ Manufacturer Specific ✔ Plant Specific ❌ Batch Specific |

Software and LCI Data Sources

| LCA Software: | openLCA v. 1.11 | ||

| LCI Foreground Database(s): | Ecoinvent v. 3.9.1 | US, RoW | Cut-off system model |

| LCI Background Database(s): | Ecoinvent v. 3.9.1 | US, RoW | Cut-off system model |

System Boundary

| Production | A1 | Raw material supply | ✔ |

| A2 | Transport | ✔ | |

| A3 | Manufacturing | ✔ | |

| Construction | A4 | Transport to site | ND |

| A5 | Assembly/Install | ND | |

| Use | B1 | Use | ND |

| B2 | Maintenance | ND | |

| B3 | Repair | ND | |

| B4 | Replacement | ND | |

| B5 | Refurbishment | ND | |

| B6 | Operational Energy Use | ND | |

| B7 | Operational Water Use | ND | |

| End of Life | C1 | Deconstruction | ND |

| C2 | Transport | ND | |

| C3 | Waste Processing | ND | |

| C4 | Disposal | ND | |

| Benefits & Loads Beyond System Boundary | D | Recycling, Reuse Recovery Potential | ND |

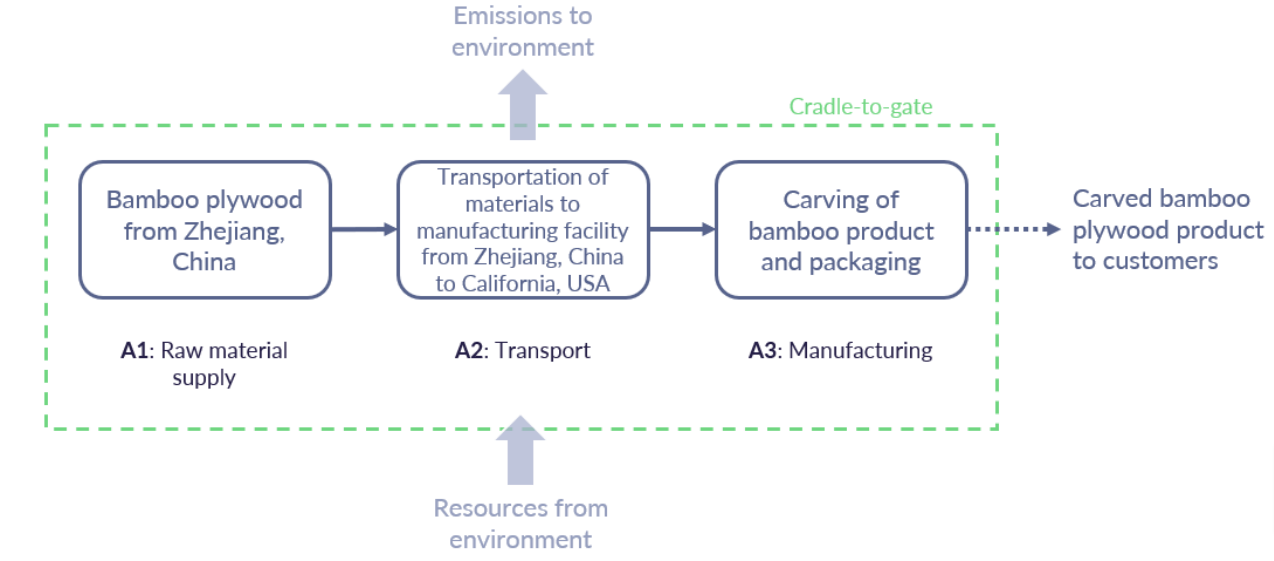

Product Flow Diagram

Life Cycle Module Descriptions

The carved bamboo plywood manufacturing process starts with growing and harvesting the bamboo poles, followed by a milling process and an assembly process. The raw bamboo is split and then milled through a double milling process and is kiln dried. Once the bamboo strips are dried, adhesive is applied to the strips and pressed face to face to produce a raw bamboo blank. This blank is then refined and multiple blanks are pressed together to form a piece of bamboo plywood during the assembly process. The bamboo plywood is then transported from Zhejiang, China to California, USA for the carving process.

Module A1 includes the raw material processing and production of bamboo plywood. Module A2 include the transport of the bamboo plywood from Zhejiang, China to California, USA. Module A3 includes the carving process, packaging, and waste management.

LCA Discussion

No cut-off criteria were defined for this analysis. All available energy and material flow data were included in accordance with the system boundary. Proxy data were used as needed in the model to capture all considered life cycle impacts.

Annual production volume and product mass were used as basis to allocate facility-level inputs, outputs, and emissions.

At each of the manufacturing plants in Zhejiang, China, a portion of the bamboo trimmings/sawdust generated is used internally as fuel at the plants to generate steam. The waste bamboo products are burned to heat boilers used during the milling process in Zhejiang, China. This approach is consistent with the PCR and ISO 21930. For the production process in A3, a mass-based allocation procedure was used for co-products leaving the system boundary. Co-products generated in module A3 are sold to make energy pellets and other products. For the Plyboo production process, mass-based allocation procedure was used. The rest of the bamboo coproducts generated are sold to make energy pellets and other products.

Results

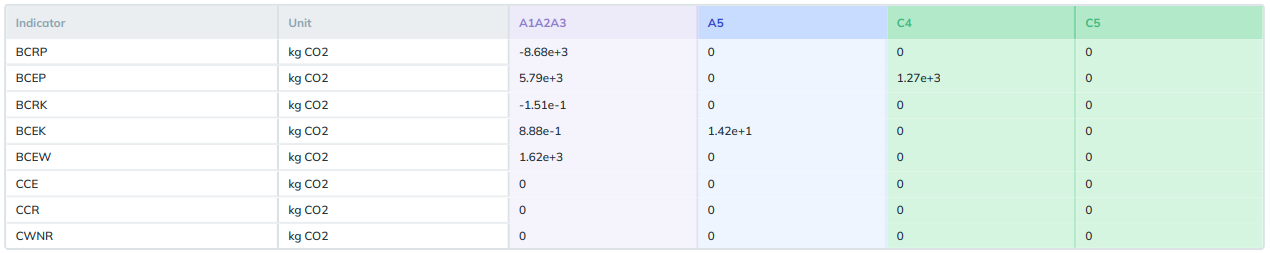

Environmental Impact Assessment Results

IPCC AJ5 –WP 100, TJACI 2.1, CML 2016

per 1 m3 of product.

LCIA results are relative expressions and do not predict impacts on category endpoints, the exceeding of thresholds, safety margins or risks.

Comparisons cannot be made between product-specific or industry average EPDs at the design stage of a project, before a building has been specified. Comparisons may be made between product-specific or industry average EPDs at the time of product purchase when product performance and specifications have been established and serve as a functional unit for comparison. Environmental impact results shall be converted to a functional unit basis before any comparison is attempted. Any comparison of EPDs shall be subject to the requirements of ISO 21930 or EN 15804. EPDs are not comparative assertions and are either not comparable or have limited comparability when they have different system boundaries, are based on different product category rules or are missing relevant environmental impacts. Such comparison can be inaccurate, and could lead to erroneous selection of materials or products which are higher-impact, at least in some impact categories.

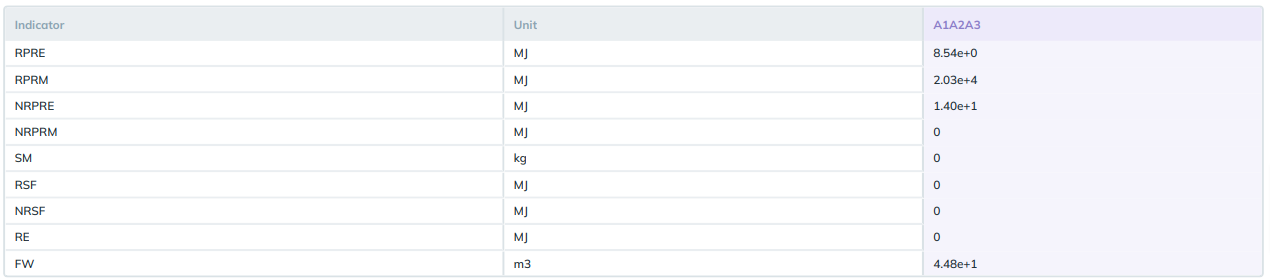

Resource Use Indicators

per 1 m3 of product.

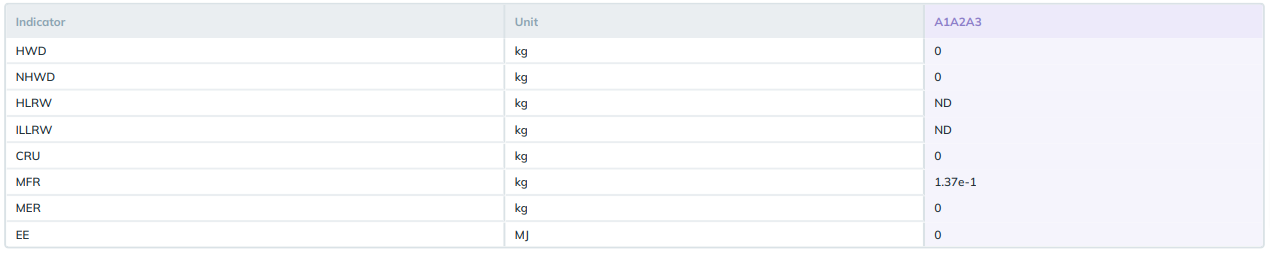

Waste and Output Flow Indicators

per 1 m3 of product.

Carbon Emissions and Removals

per 1 m3 of product.

Interpretation

The results of the LCA indicate that the electricity and steam generation for the milling and assembly plant are the largest contributors to the Smith & Fong product footprint across impact categories. The adhesive is also a significant contributor. Impacts of adhesive are driven by the adhesive feedstocks. Inbound transport of bamboo and adhesive to the plant is included and is a small contributor to the product footprint.

The study timeframe is for the year 2022 for Smith & Fong manufacturing in Zhejiang, China. This study does not include comparisons or benchmarking. Environmental declarations from different programs based upon different PCRs may not be comparable.

While this EPD does not address landscape level forest management impacts, potential impacts may be addressed through requirements put forth in regional regulatory frameworks, ASTM 7612-15 guidance, and ISO 21930 Section 7.2.11 including notes therein. These documents, combined with this EPD, may provide a more complete picture of environmental and social performance of wood products.

While this EPD does not address all forest management activities that influence forest carbon, wildlife habitat, endangered species, and soil and water quality, these potential impacts may be addressed through other mechanisms such as regulatory frameworks and/or forest certification systems which, combined with this EPD, will give a more complete picture of environmental and social performance of wood products.

EPDs can complement but cannot replace tools and certifications that are designed to address environmental impacts and/or set performance thresholds – e.g. Type 1 certifications, health assessments and declarations, etc.

National or regional life cycle averaged data for raw material extraction does not distinguish between extraction practices at specific sites and can greatly affect the resulting impacts.

Accuracy of Results: EPDs regularly rely on estimations of impacts; the level of accuracy in estimation of effect differs for any particular product line and reported impact when averaging data. Variability was estimated in this EPD by mass allocation.

Additional Environmental Information

Smith & Fong have the following certifications: FSC® Chain of Custody Certificate, Plyboo ® Health Product Declaration, and a Declare Certificate. Please contact Dan Smith at dan@plyboo.com for copies of certifications.

References

ACLCA. (2018). ACLCA Guidance to Calculating Non-LCIA Inventory Metrics in Accordance with ISO 21930: 201R.

Bare, J. (2011). TRACI – The Tool for the Reduction and Assessment of Chemical and other Environmental Impacts. CLEAN TECHNOLOGIES AND ENYIRONMENTAL POLICY.

Guinee, J.B. et al. (2002). Handbook on life cycle assessment. Operational guide to the ISO standards. I: LCA in perspective. IIa: Guide. IIb: Operational annex. III: Scientific background. Dordrecht: Kluwer Academic Publishers.

IEA. (s.f.). China. Obtenido de https://www.iea.org/countries/china

IPCC. (2021). Climate Change 2021: The Physical Science Basis. IPCC.

ISO. (2006). 14025:2006 – Environmental labels and declarations – Type III environmental declarations – Principles and procedures. Geneva: International Organization

of Standardization.

ISO. (2006a). 14040:2006GAmd.1:2020 V Environmental management P Life cycle assessment P Principles and framework. Geneva: International Organization of

Standardization.

ISO. (2006b). 14044:2006/Amd.1:201R/Amd.2:2020 – Environmental management – Life cycle assessment – Requirements and guidelines. Geneva: International Organization for Standardization.

ISO. (2013). 14046:2013GAmd. 2020 – Environmental management water footprint – Principles, requirements and guidelines. Geneva: International Organization for

Standardization.

ISO. (2017). 21930:201RGAmd.1:2023 V Sustainability in buildings and civil engineering works – Core rules for environmental product declarations of construction products and services. Geneva: International Organization of Standardization.

UL Environment. (2022). Part B: Structural and Architectural Wood Products EPD Requirements. v1.1. 7L Environment.

UL Environment. (2018). Part A: Life Cycle Assessment Calculation Jules and Report Requirements. v4.0. 7L Environment.

Wernet, G., Bauer, C., Steubing, B., Reinhard, J., Moreno-Ruiz, E., & Weidema, B. (2016). The ecoinvent database version 3 (part I): overview and methodology. The

International Journal of Life Cycle Assessment, 1218-1230.